Using the tester to determine if the ignition coil is faulty or another electrical component is:

#Testing spark plug how to#

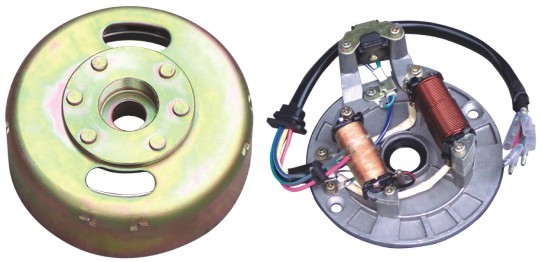

How to test the ignition on a small engine This process continues with every revolution of the crankshaft until the engine is shut off. The momentum of the spinning flywheel provides enough force to push the piston back up where the spark plug will again ignite newly drawn in fuel and air. This drives the piston back down through the cylinder to rotate the crankshaft. The spark plug fires and ignites the fuel and air mixture. On both four-cycle and two-cycle engines, fuel and air will enter the cylinder where it is compressed by the piston as it travels to the top of the cylinder. The magnetic field induces electricity, allowing the ignition coil to send voltage to the spark plug. The flywheel has permanent magnets built into it, and as it rotates past the ignition coil, a magnetic field is created. The rotating crankshaft connects to the piston which moves up-and-down within the cylinder and ignition process begins. When that start button is pressed, the ignition key turned, or the rope is pulled, the starter turns the flywheel which, in turn, rotates the crankshaft.

Smaller four-cycle engines, and all two-cycle engines, rely on the operator to pull a starter rope to fire the engine up. The main difference between the two types of engines is that the four-cycle engine requires two revolutions of the crankshaft and piston to draw the fuel and air into the cylinder, ignite it, then exhaust the combustion gases the two-cycle engine requires just one revolution to do the same thing.Īdditionally, a larger four-cycle engine may utilize an electric start feature that allows the engine to be turned over by using an ignition key or a start button. Larger outdoor power equipment, such as lawn mowers, snowblowers, pressure washers, wood chippers, and more heavy-duty tillers will depend on four-cycle engines to provide the necessary torque, whereas smaller hand-held equipment, such as string trimmers, chainsaws, pole pruners, and leaf blowers, can get by with the lesser amount of torque provided by a two-cycle engine. Remind me about the difference between a two-cycle and a four-cycle engine? An ignition tester will speed up the troubleshooting process by allowing you to quickly determine if the spark plug or ignition coil is faulty on most two-cycle and four-cycle engines.

#Testing spark plug professional#

This can be done by using an ignition tester, a relatively inexpensive accessory that should be part of every tool box, whether you’re a professional landscaper or a do-it-yourself backyard enthusiast. One way to do this is to test the engine’s ignition system. To get your outdoor power equipment up and running as quickly as possible, you’re going to need to identify the source of the problem. The cause could be a defective spark plug, a malfunctioning ignition coil, a restricted carburetor, a clogged fuel filter, or something else entirely. Or, perhaps, you’re turning the ignition key on your lawn mower only to hear a brief straining whine before… silence. You keep pulling the starter rope on your gas-powered string trimmer until it feels like you’ve dislocated your shoulder, but the engine won’t fire up.

0 kommentar(er)

0 kommentar(er)